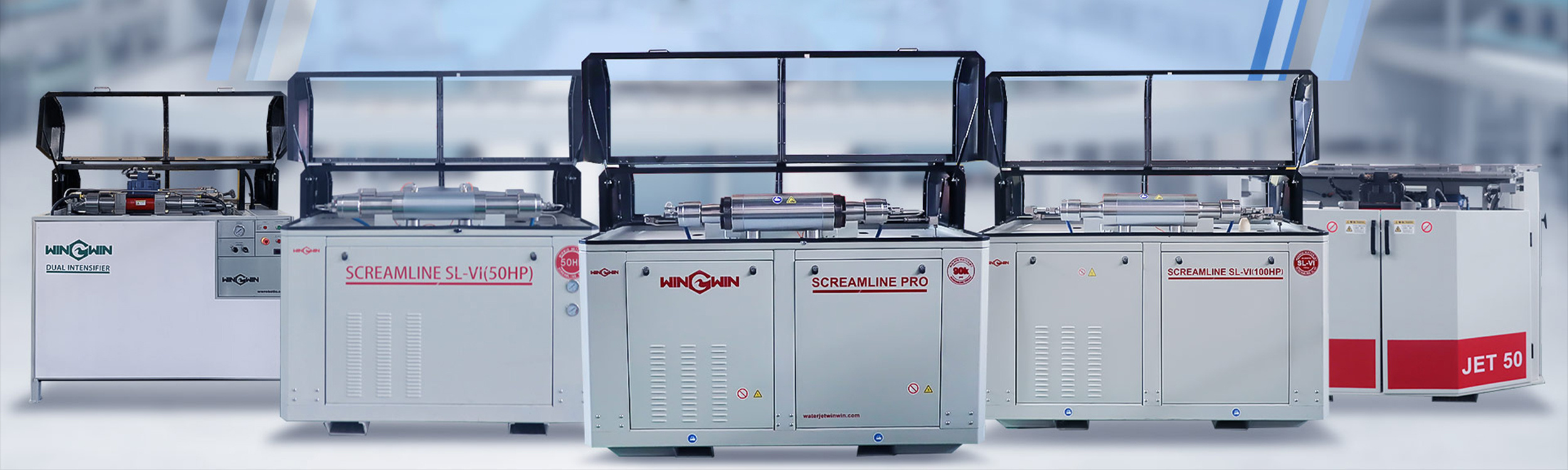

WINWIN Waterjet At The Metalworking Exhibition In Russia

2024-04-20

author:

WINWIN was invited to Russia to participate in the exhibition. The content of the exhibition was equipment, devices and tools for the metalworking industry.

The cutting range of a waterjet cutting machine is affected by the thickness of the material being cut. Waterjet cutting can effectively handle materials of various thicknesses, from thin sheets to thick blocks. The maximum thickness that a waterjet cutting machine can handle is generally higher for thick materials compared to thin materials. A machine's specifications, such as maximum pump pressure and horsepower, determine its ability to cut different material thicknesses.

Waterjet cutting machines can use different cutting strategies for thick and thin materials. When cutting thick materials, machines often use slower cutting speeds and multiple passes to achieve the desired cut. In contrast, with thin materials, machines can take advantage of faster cutting speeds and fewer passes to maintain efficiency while ensuring accuracy.

Waterjet cutting machines can operate at higher cutting speeds when cutting thin materials compared to thick materials. Thinner materials offer less resistance to the cutting flow and cut faster. The machine's ability to maintain precision and accuracy is especially important when cutting thin materials. Waterjet cutting machines can help factories speed up production and increase productivity.

Cutting thick materials often requires a sturdy material support system, such as a sturdy cutting table or additional clamps to handle the weight and stability of the material. Thin materials may not require as much support, but will still need to be properly secured or clamped to prevent movement during cutting. Thinner materials are more susceptible to deformation or warping from excessive heat or pressure, so machines must be properly calibrated and controlled to ensure accurate cuts.

Thick materials often require more abrasive particles to assist in the cutting process. Coarser abrasives are typically used for cutting thicker materials to enhance cutting efficiency. In contrast, for thin materials, finer abrasives are utilized to achieve finer cuts without causing excessive damage.

By choosing to cooperate with WINWIN, we can save costs and improve productivity for our customers to a great extent, helping customers take the lead in the highly competitive market. WinWin's robotic waterjet cutting equipment has won international acclaim and is widely adopted by leading manufacturers in a variety of industries.

Scan the QR code

Contact us

Email:service@winwinwaterjet.com

Address:63-32 Qixing Street, Shenbei New District, Shenyang City, Liaoning Province