AI-powered adaptive waterjet cutting systems

2025-07-02

author:

🚀 AI-Enhanced Waterjet Cutting

Modern waterjet systems are now integrating artificial intelligence (AI) and machine learning (ML) to enhance precision, efficiency, and automation.

🔹 Key Features of AI-Enhanced Waterjet Cutting:

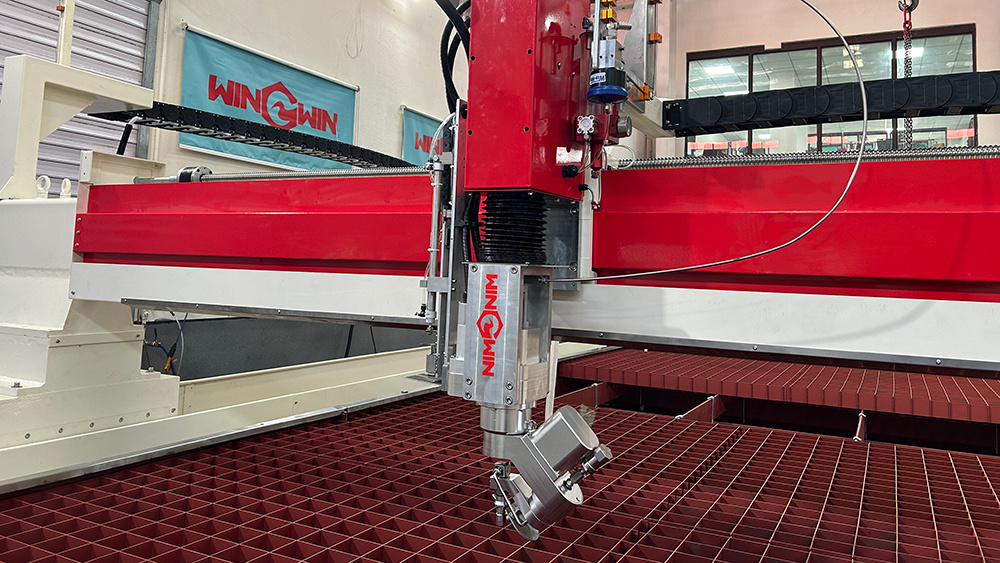

Real-Time Adaptive Cutting

AI algorithms adjust pressure, speed, and abrasive flow in real time based on material properties.This reduces material waste and improves cutting accuracy.

Predictive Maintenance

IoT sensors monitor machine wear and tear, predicting failures before they happen.Automated alerts notify operators when parts (like nozzles and pumps) need replacement, minimizing downtime.

Automated Nesting Optimization

AI-powered software optimizes material usage by arranging parts more efficiently on the cutting bed.This significantly reduces material waste and improves cost-effectiveness.

AI-Driven Path Correction

Advanced AI models analyze cut quality in real time and adjust the cutting path to maintain precision.This is especially useful for complex geometries and high-precision industries like aerospace and medical device manufacturing.

Integration with Industry 4.0

New waterjet machines are now connected to cloud-based platforms, allowing remote monitoring and control. This enables manufacturers to integrate waterjet cutting into fully automated smart factories.

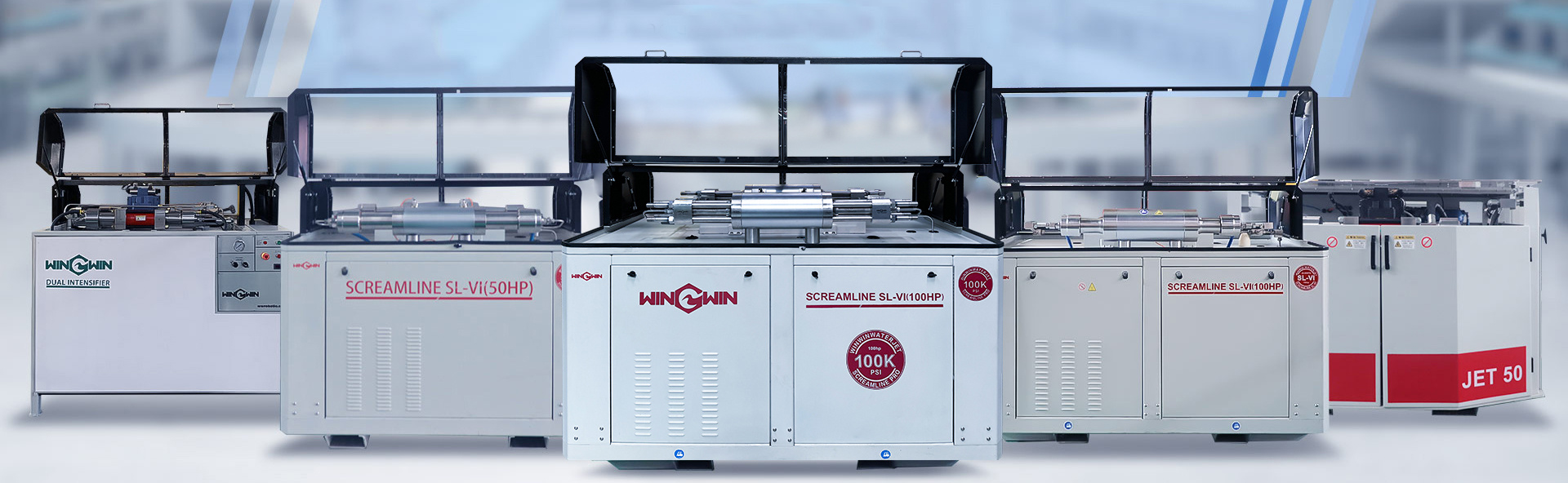

🔹 Example of a New AI-Integrated Waterjet System

We will introduc AI-enhanced waterjet systems that self-optimize cutting parameters based on material type, thickness, and desired finish. also launched smart waterjet solutions with IoT-enabled predictive analytics.

Scan the QR code

Contact us

Email:service@winwinwaterjet.com

Address:63-32 Qixing Street, Shenbei New District, Shenyang City, Liaoning Province