Win Win Waterjet Unveils Advanced Robotic Waterjet System for Automotive Interiors

2026-03-03

author:

September 28, 2025 – Win Win Waterjet, a leading innovator in precision cutting solutions, has announced the successful commissioning of a groundbreaking new project for a major automotive components manufacturer. This state-of-the-art system is specifically engineered for high-volume, high-precision cutting of automotive interior materials, marking a significant leap forward in production efficiency and quality.

The centerpiece of this new installation is a sophisticated dual-FANUC robot waterjet cutting cell. Equipped with two high-precision M710iC series robots, the system can perform complex, simultaneous cuts on multiple parts. The M710iC robots are renowned for their robust construction, high-speed motion, and exceptional repeatability, making them ideal for the demanding tolerances required in automotive interior production, such as for dashboards, floor mats, door panels, and headliners.

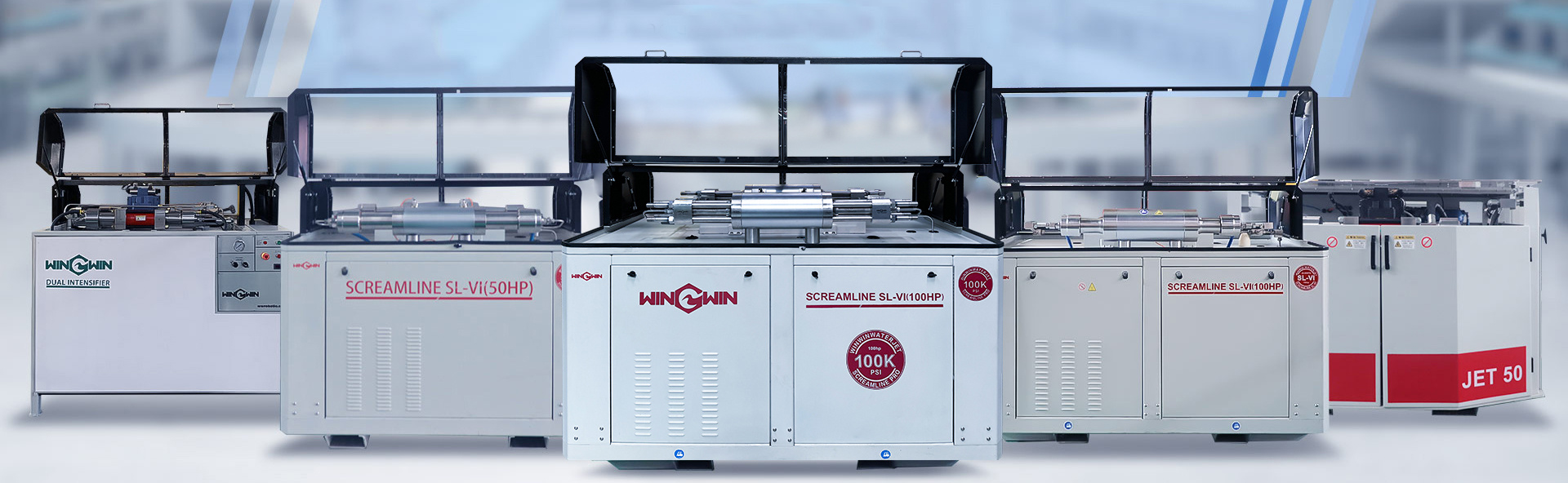

Powering the waterjet cutting heads is a dual-intensifier high-pressure pump rated at 50 horsepower. This powerful pump consistently delivers a stable, ultra-high-pressure water stream, which is critical for achieving clean, burr-free edges on a variety of materials. From plush carpets and synthetic fabrics to composite sound-dampening materials, the system ensures a superior cut quality without fraying or delamination, a common challenge with traditional cutting methods.

"This project represents our commitment to pushing the boundaries of waterjet technology," said a senior project engineer at Win Win Waterjet. "The synergy between the dual FANUC robots and our powerful 50HP pump creates an unparalleled solution for the automotive sector. Our client will benefit from dramatically increased throughput, reduced material waste, and flawless part consistency, all while eliminating the thermal damage or harmful fumes associated with laser or blade cutting."

The new system is expected to significantly enhance the client's manufacturing capabilities, allowing for greater design flexibility and faster response to market demands. By automating the cutting process with such advanced technology, Win Win Waterjet continues to solidify its position as a key technology partner for industries where precision, speed, and material integrity are paramount. This project underscores the growing trend of adopting advanced robotic waterjet systems for delicate and complex cutting applications within the global automotive supply chain.

Scan the QR code

Contact us

Email:service@winwinwaterjet.com

Address:63-32 Qixing Street, Shenbei New District, Shenyang City, Liaoning Province